Cutting Methods

Depending on the label’s material thickness, size, chosen printing method, total order volume, and design complexity, different cutting methods can be applied. Below we take a closer look at the options available for label materials: plotter cutting, laser cutting, and die cutting.

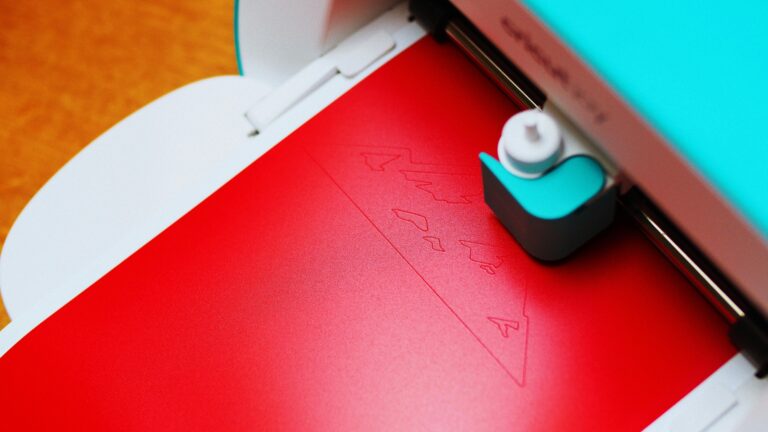

Plotter Cutting

This method uses a plotter machine equipped with a sharp blade mounted on a special cutting head. The desired design or shape is created in a computer program and sent to the plotter as a vector file. The plotter then follows the file’s path, moving the blade across the material to cut the required shape.

In our printing house, this method is mainly used for samples or very small projects. Which are typically delivered as sheets.

Laser Cutting

Laser cutting uses a powerful beam (or multiple beams) directed by a computer-controlled system to follow the shape and cut the material with precision. It can be used for a wide range of substrates, but each machine has its own limitations in terms of supported materials and maximum cutting sizes.

This method is ideal for small production runs, as laser cutters excel at precise, detailed shapes. Due to heat exposure, the material around the cutting line may discolor or slightly melt, especially with film or plastic-based substrates. This creates a small edge around the label. Consider this effect, especially with dark labels on dark packaging, as edge contrast can become noticeable.

Die Cutting

For die cutting, a special metal cutting tool (called a die) is created in the required size and shape. The die is placed on a magnetic cylinder in the cutting machine, and with applied pressure, it cuts through the label material’s top layer down to the backing paper.

Although setup time is slightly longer than with laser cutting, the process itself is faster. Another advantage is the clean, smooth cut with no impact on printed colors or material, unlike laser cutting which can create raised edges. Additionally, mechanical die cutting has no material limitations.

Summary

Overall, die cutting is considered the industry standard and is the most widely used method for producing custom label shapes. Laser cutting, however, is a relatively new technology that is gaining popularity, particularly because it eliminates the need to purchase custom dies for small or unique projects and allows for more creative freedom in label shapes.